Track Design for Australian Monorails

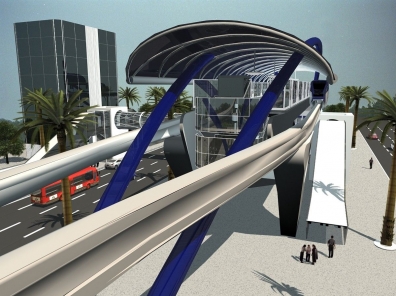

Art rendering of monorail track suitable for Australian cities. (The original Image was for the new monorail in São Paulo, Brazil: Skyscraper City) |

- Double Track: In all cases double track is recommended. As with any rail system having a single track places severe limitations on service frequency. In the case of monorail the savings from having a single track are limited and space is unlikely to be an issue. It is possible that in some case the left and right tracks could be routed on either side of some obstacle for a short distance. In the CBD it may be useful to have a split station hosted on buildings on opposite sides of the street.

- 30 meter column spacing. In general the maximum spacing for column supporting concrete beams would be used which is 30 meters. Greater spans require use of steel beams or concrete beams supported by steel.

- Guide rails: These will be arched as used on the Dubai and São Paulo monorails. The pre-cast guideway sides and base will have a polished 'class-1' finish. The top of the guideway is finished so as to provide adequate grip for the tyres.

- Pillars: The pillars are 1.2 meters in diameter and will have a high quality finish. See images of the São Paulo Monorail (under construction). Pillars will be sized to ensure at least 4.3 meter clearance over all major roadways. Power and other cabling will be run up a hollow central core.

- Pillar Base Guard: The base of the column will be fitted with a non-structural guard to absorb vehicle impacts. (The pillar itself goes through the guard into the ground.) The guard will come in two halves to allow replacement if damaged. The colouring and finish is yet to be determined, but would not be grey.

- Vertical Gardens: We recommend all support columns and stations are installed with extensive vegetation covering most of the vertical surfaces to create

living walls.

This is both to improve aesthetics of the pillars and to discourage

vandalism.

The climbing fig Ficus pumila (Wikipedia) - Tree Way: As shown in the above examples a "tree way" will be created underneatth the monorail track wherever possible. Where trees are already present as many as possible will be retained and addional plantings created.

Monorail Guideway Standards

Australia's rail system has been adversely impacted by the adoption of various rail gauges across the continent. A similar mistake can be made with both straddle beam Urban Transit Monorails as well as with Maglev Monorails.

The objective is to have a standard monorail guideway adopted for both Urban Transit Monorails and Maglev Monorails.

In selecting particular technologies and providers:

- A single guideway type for Urban Transit Monorails should be selected for each City if not the whole country.

- At the point of selection the selected manufacturer would have to agree to reasonable licence fees for their technology to be used going forward if they wish their technology to be the standard for the State if not Australia.

- The selected manufacturer would also need to agree for others to manufacturer monorail vehicles or guideway of the agreed guideway standard should the selected manufacturer cease to exist.

No Advertising!

Artists impression of an LA monorail running over the flood channels. (http://lavisions.blogspot.com.au) |

Monorail trains, stations and pillars will carry NO advertising.

This needs to be written in to key contract documents to prevent future operators covering monorail infrastructure with unsightly billboards.

Automation

Monorails are well suited to automatic driving due to the lack of any level crossings, pedestrians or other unpredictable interuptions.

However it is anticipated that trains would generally carry at least one crew member to perform the following tasks:

- Safely closing the doors and starting the train towards the next station.

- Providing security and discouraging vandelism.

- Providing First Aid to ill passengers.

- Emergency management.

During late night or early morning operations these functions may on occasions be performed by remote control from a command room. At these times only accredited passengers may use the system.

Train automation systems will not be connected to the internet at any time.

Capacity

Capacity depends on the time between services, the number of carriages and the loading per square meter. Loading Capacity (Passengers per hour per direction) can then be calculated.

The following data is from Hitachi Rail for their medium-sized monorail product with a loading of four person's per square meter which would be considered the maximum loading in Australia.

Note that the system can be expanded over time. Initially two-car trains could be used at 10 minute intervals and then gradually ramped up to eight-car trains every three minutes.

Eight-carriage trains would be about 100 meters long.

Passengers per hour per direction

| Headway (min) |

No. of Trains (per hour) |

2-Car Train | 3-Car Train | 4-Car Train | 8-Car Train |

|---|---|---|---|---|---|

| 3 | 20 | 3,680 | 5,740 | 7,800 | 15,600 |

| 4 | 15 | 2,760 | 4,305 | 5,850 | 11,700 |

| 5 | 12 | 2,208 | 3,444 | 4,680 | 9,360 |

| 6 | 10 | 1,840 | 2,870 | 3,900 | 7,800 |

Trains

Ideally one manufacturer would be contracted to build many urban monorail systems under an agreed long-term formula. While being profitable for the manufacturer the formula would also ensure monorail system operators were not likely to be exposed to unreasonable maintenance and part replacement costs during the life of the system.

- Hitachi Monorail Systems

Hitachi Rail is the leading manufacturer of high-capacity ALWEG monorail systems with over four decades of experience.

- Bombardier Monorail

Visit the Bombardier site for more information about bombardier's automated monorail 'Innovia 300' and also this PDF.

- Scomi Monorail

Visit the Scomi site for more information about Scomi's monorail product.

Station Design

Below are three types of station configuration.

In all cases multiple lifts, stairs and escalators service the platforms. A concourse one level down links the platforms and provides walkway access to either side of the street as appropriate. Platforms and walk ways are fully enclosed and have platform screen doors.

- Low Capacity Station: This has a single platform in the centre with tracks passing on each side.

- Medium Capacity Station: In this configuration the tracks are in the centre and the platforms are on the

edge.

This design provides more protection from the elements and means the platform screen doors need only be waist high. - High Capacity Station: For high capacity stations with space for a larger overall footprint

platforms can be provided on both sides of each track. This allows the central platform to be the passenger entry platform

while the edge platforms are for passenger exit. This minimises dwell times at these stations by providing a smoother flow of passengers.

All the platforms are about 100 meters long and would be mass produced to cut costs.

Station Images

Station design has not yet been determined but here are some examples from existing monorail lines to indicate what is feasible.

Island Platforms

An island platform station on the Palm Jumeirah Monorail in Dubai.

Art rendering of a proposed new monorail station for São Paulo, Brazil.

Edge Platforms

Maihama station, Tokyo (Image: Wikipedia)

Under the Track

Wherever possible a 'treeway' will be planted underneath the monorail track. Along many suggested routes trees are already in place, in this case every effort would be made to retain as many trees as possible.

|

View Larger Map Street View of Naha Monorail, Okinawa. We aim to have more aestehtic pillars in place for Australian monorails. (If Street View does not display then click HERE and click street view.) |

Long Spans

Hitachi used braced steel girders to support the track through over long sections without pillars and for tight curves track for it's Okinawa Monorail.

|

View Larger Map Street View of Naha Monorail, Okinawa showing a long curved span. (If Street View does not display then click HERE and click street view.) |

Offset Guideway Support

Offset track can be used where a central pillar is impractical further increasing design flexibility.

Modified image of Okinawa monorail (Hitachi system). |