Manufacturers

1) Transrapid Maglev

ThyssenKrupp's Transrapid Maglev System pioneered the practical use of maglev trains and built the world's only commercial system in Shanghai.

Unfortunately ThyssenKrupp is no longer actively promoting the technology.

Most of the data on this page is regarding Transrapid as CRRC maglev data is not available.

2) CRRC Maglev

As at June 2020 five test cars were under development, with a full prototype capable of 600km/h expected by 2021. In 2019 China announced plans for a 200km maglev line in Hubei province to to allow 600km/h testing.

CRRC Maglev prototype. (Image: CRRC) |

China's CRRC is now looking to build maglev trains that are similar to Transrapid's proven design.

3) Japan Railways Superconducting Maglev Trains

Japan Railways SC Maglev. (Image: CRRC) |

The Superconducting Maglev being developed by Central Japan Railways offers even higher speeds than Transrapid Maglev. In April 2015 they set the world record of 603 km/h - although since the maximum speed it can pass another train is 513 km/h it does not offer much practical speed advantage over Transrapid Maglev unless trains never pass at full speed.

The SC Maglev runs in a U-shaped channel* and uses superconducting magnets for levitation and propulsion.

The drawback with this technology is it is essentially a straight line system with very limited tolerance of curves or gradients and also has a comparatively wide guideway compared to the Transrapid monorail guideway. However, it should still be investigtated.

See also the article below on Consolidated Land and Rail Australia (CLARA).

(* As the guide-way is wider than the vehicle the SC Maglev is not a monorail)

Why Maglev?

Problems with conventional High Speed Rail (HSR)

- Conventional HSR is too slow for Australia and would result in most trips from Melbourne to Sydney taking over three hours which is not competitive with air travel.

- Conventional HSR has a lower tolerance of small radius turns and steep gradients which requires more tunnels and bridges.

- Elevated conventional fast rail has a high visual impact due to the large structure required including overhead power lines and heavy guard rails to prevent derailment.

- Wide conventional fast rail easements need to cut into the landscape due to their low tolerance of gradients and tight curve radii. Thousands of bridges are needed for roads and rivers along with continuous high fencing on both sides. The rail easement divides farms and natural habitats.

Tunnelling Costs

In Victoria the government has estimated that the Melbourne Metro will cost $11 billion for 9 km. Meanwhile Infrastructure Australia is estimating HSR tunnelling will only cost $170 million per kilometre.

It is extremely difficult to reconcile these two numbers. The only way both numbers could be correct is if the five underground stations on the Melbourne Metro account for 83% of the $11 billion cost with only 17% due to the cost of the actual rail tunnel.

If Infrastructure Australia has under estimated the tunnel costs for HSR this would have a huge impact on the viability of their HSR proposal since it includes 144 kilometres of tunnels.

If fast rail tunnels really do only cost 17% of the cost of slow rail tunnels then maglev trains could run underground in urban areas as well.

The Transrapid Maglev Solution

Maglev high-speed rail is the best high-speed rail system for Australia.

- Transrapid Maglev track is designed to be elevated. Elevating fast rail avoids tunnelling and reduces the impact on the landscape.

- Transrapid Maglev trains are attached to the guide-way so cannot be derailed.

- Transrapid Maglev track can handle tighter curve radii and gradients than conventional fast rail further reducing the need for expensive tunnelling.

- Maglev track is completely separate from all existing rail track so neither impacts the other.

- At $40 to $50 million per kilometre the Transrapid Maglev system compares well with many other transport systems.

- Transrapid Maglev trains can operate at up to 500 km/h. This is particularly useful in Australia where larger distances need to be covered.

- Other characteristics of Transrapid maglev system are similar or slightly better than conventional fast rail including construction cost, running costs, noise levels, capacity and acceleration.

- While Transrapid Maglev is new compared to other transport technologies the Shanghai Maglev has operated continuously since 2004 proving the concept. The German maglev test track at Emsland operated between 1984 and 2013.

- Unlike Europe or Japan Australia does not already have a conventional high speed train network. We have a clean slate so can pick the optimum technology.

Mitigating risks with a single-vendor solution

Unlike conventional rail the Transrapid technology is owned by Transrapid. Obviously Australian governments would not want to be locked into buying everything from Transrapid for ever so before this technology could be used the relevant government would need to negotiate to obtain an open licence to use the Transrapid technology within Australia.

This would allow sourcing of new vehicles, track and components from a variety of manufacturers in the future irrespective of whether Transrapid still existed or not.

If such an agreement could not be reached this technology should not be used.

What is Maglev?

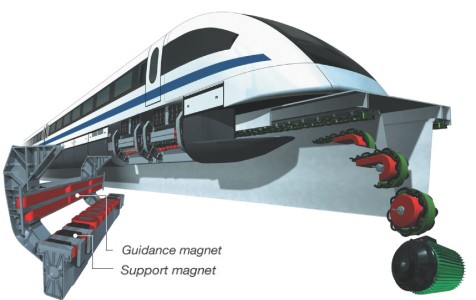

A cut away diagram of the maglev system. (Image: Transrapid) |

Instead of wheels, Maglev Fast Rail systems use magnets to magnetically levitate the train above the track. The track itself is an electric motor that has been unwound into a long linear motor. The linear motor propels the Maglev train along the track at speeds of up to 500 km/h.

There is no friction between the train and the track, there are no overhead wires. Inside the train the magnetic field strength is one tenth of the magnetic field of a hair-dryer. The train levitates using on-board batteries which can keep the vehicle floating for up to an hour without any mains power supply to the track. Outside there is no noise from steel wheels on steel track, no sparking from overhead wires.

Guidance magnets located on both sides along the entire length of the vehicle keep the vehicle laterally on the track. (Image: Transrapid) |

As seen in this image of a CRRC prototype carriage, CRRC seems to be taking the same approach as Transrapid rather than attempting the more complex Japanese super conducting maglev model. (Image: CRRC) |

Video

Transrapid Test Track Video

Note that following the success of the Shanghai Maglev this test track at Emsland has now been dismantled. However, these videos still provide an excellent overview of the technology.

|

Transrapid Test Track Video. (Transrapid Test Track YouTube Video) |

Flying on the Ground Video

|

Flying on the Ground Video. (Mobile: Flying on the Ground YouTube Video) |

Maglev Interior

Maglev carriages are 3.7 meters wide - conventional trains are about 3 meters wide. The wider carriages open up more options for seating plans. We believe 3 by 2 seating would be about right for Australia.

Three by three seating

|

Image of the interior of a Shanghai Maglev train showing economy 3 by 3 seating. These seats are too narrow for the average Australian. |

Two by two seating

Transrapid TR09 interior. This shows 2 by 2 seating. |

CRRC Maglev Interior

CRRC Maglev prototype interior. (CRRC web site) |

Technical Data

Energy Efficiency

The graph below shows Transrapid Maglev energy efficiency, as stated by Transrapid on their web site and in their official submission to the Victorian State Government.

Critics have suggested that energy requirements for maglev are massive and several new nuclear power stations would be needed to run the maglev track. Impartial analysis and inspection of the Shanghai maglev track should be able to uncover any such hidden nuclear power stations and determine exactly what the energy requirements are. We note that Transrapid claims their trains can continue to levitate on battery power alone in the event of a power failure to the track.

CO2 Emissions

Transrapid CO2 emissions.

Magnetic Field Strength

Transrapid magnetic field strength inside the cabin compared to a hair dryer.

Curve radii

The transrapid web site gives data four points of data for curve radii. Plotting this as a graph enables estimation of minimum curve radii for any given speed.

Note that at 200 km/h maglev is able to turn through curves with a radius of just 705 meters. This is one of the key benefits of this technology.

Maintenance Costs

Due to the non-contact nature of the technology operating costs are greatly reduced as are system downtimes.

Acceleration

Transrapid maglev trains are able to accelerate much faster than conventional trains resulting in faster trip times.

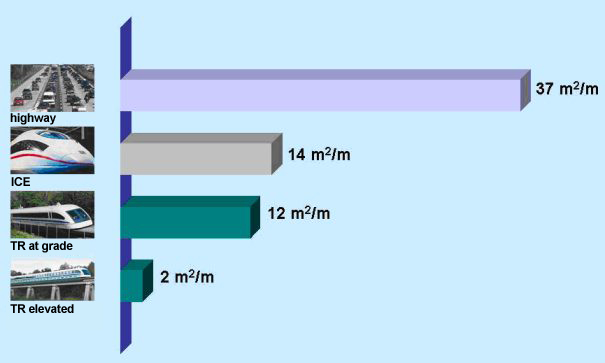

Land Usage

Elevated transrapid maglev has very low land usage which is a key advantage when trying to thread new high speed rail links in and out of congested urban areas.

Tunnels

Tunnels are best avoided as irrespective of the guideway system they are extremely expensive and risky. However, maglev tunnel dimensions are somewhat smaller than conventional rail tunnels.

|

Maglev tunnel dimensions. Center to centre distance depends on speed. A cross sectional area of 180m2 is required for double track with trains running at 400 km/h. (Transrapid) |

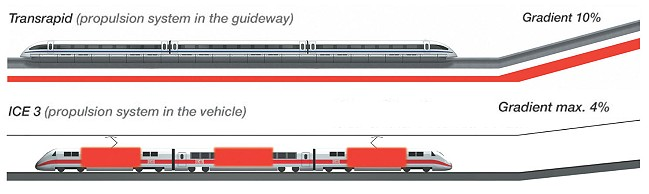

Gradients

As the Transrapid is capable of climbing steep gradients (ten percent compared to four percent for normal rail roads) and able to handle tight curves (1950 meters at 300 km/h compared with 3200 m for normal rail roads), it is possible to flexibly adapt its guide way to the landscape and to have it tightly follow existing roads, rail road tracks, and power lines.

Transrapid maximum gradients vs. conventional fast rail. (Transrapid) |

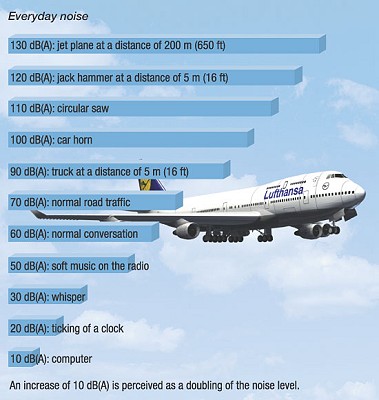

Noise

At speeds around 200 km/h, you can hardly hear the Transrapid. It can quietly hover through cities and urban areas because with to its non-contact technology, there is neither rolling nor engine noise. At higher speeds, there is only the noise of the wind. At 300 km/h, the Transrapid maglev vehicle develops only as much noise as light rail trains travelling at 80 km/h, and even at speeds above 400 km/h, it is not much louder than considerably slower rail roads.

(Monorails Australia is interested in seeing if extra baffles could be mounted along the track to absorb more sound from the maglev train in selected areas.)

|

|

Air Turbulence

When the Transrapid passes by it generates minimal turbulence. Thanks to the aerodynamic optimization of the Transrapid vehicle, there is nothing more than a slight gust at a distance of 2 meters when the Transrapid passes by at a speed of more than 380 km/h. There is no perceptible air movement under the elevated guide way and the air movement produced by the vehicle on at-grade guide way at a speed of 330 km/h is only as strong as a moderate wind.

|

Freight

Transrapid maglev is quite capable of carrying freight. Freight trains could be scheduled to run in off-peak times or else the first and last segments could be dedicated to carrying freight with the central segments carrying passengers.

A cut-away image of a Transrapid maglev freight train. (Image: Transrapid) |

Assembly of Modular Track

The highly modular track design speeds up track construction, keeps costs down and maintains high quality.

As the track is mostly elevated anyway the cost and complexity of dealing with bridging many small features like roads and rivers is avoided. In farmland and natural habitat people, animals and equipment can easily move under the guideway.

'At Grade' track under construction for the Emsland test track. Girder completely equipped with Stator Packs and Cable Windings. (Image: US Maglev Coalition) |

The windings are added to the track segments in the factory.

Preparation of the Long Stator Winding. (Image: US Maglev Coalition) |

Why aren't there more Maglevs?

High speed rail was pioneered in Europe and Japan many years before maglev became a viable system in the late 1980's. By the time maglev was an option an extensive network of conventional rail lines had been established across Europe and Japan.

In this context any new high speed line is most likely to use conventional rail technology to fit in with the rest of the network.

Additionally the distances involved in Japan and Europe have not demanded speeds of more than 350 km/h, although now Japan is looking at its own maglev solution.

The lack of extensive maglev networks has been a major handicap for maglev as there is great resistance to trying anything new or different.

Conventional high speed rail lines in Europe - little wonder Maglev doesn't get added now. (Wikipedia). |

In Australia we have a clean slate with no fast rail and large distances to cover so we should be looking at what is best for us, not what has evolved overseas.

Other Criticism

Maglev fast rail has attracted substantial criticism, most notably from Sir Rod Eddington, former head of Infrastructure Australia.

The key criticisms are as follows:

- Lack of Use

"The most powerful evidence to dismiss maglev is that it does not work anywhere in the world. [Even the Pudong system] is a relatively small stretch. It is not even to downtown Shanghai; it is just to Pudong." Rod Eddington (April 2007).

Responses

(a) Further human progress will be very difficult if all new technologies are dismissed because they are not already in use.

(b) Where the Shanghai maglev was built is not relevant to a discussion of the viability of the technology. - Speculative Technology

Maglev is "speculative technology" with "fuzzy" economics. Rod Eddington (April 2007).

Responses

(a) The Shanghai Maglev and the Emsland test tracks have proven that Transrapid's maglev system works. Various other maglev projects including JR Maglev also prove the technology is viable.

(b) The per - kilometre cost of building the Shanghai maglev was similar to other elevated fast rail systems. The costs quoted by Transrapid for Australian maglevs are also similar to other fast rail and in fact cheaper than many conventional rail projects undertaken in Australia recently. - Power Consumption

Maglev is too power hungry.

Responses

(a) Transrapid has explicitly stated that its system uses less power than ICE 3 high speed trains in its submission to the Victorian Government. Deliberately lying to the government would be a serious matter. Appropriate independent study of the Shanghai facility should be able to quickly establish the facts.

(b) We note the capability of Transrapid maglev to continue to levitate for one hour after losing power using on-board batteries. - Incompatibility

Maglev is incompatible with old rail technology.

Responses

(a)This is correct but fast rail systems (i.e. over 250 km/h) of whatever technology need to be built on new tracks or guide ways. They cannot operate in between heavy freight on existing steel rail track. Given new track has to be laid the point is moot.

(b) New technology is very often incompatible with old technology.

(c) Transrapid maglev freight trains are compatible with standard air-freight containers. - Cannot use multi-platform stations

For some reason the 2013 Infrastructure Australia study concluded that maglev could not be used in a multi-platform scenario.

The report does not make clear what is meant by this. Clearly maglev points are functional and so could be used to direct maglev trains to as many platforms as desired. Since the trains are automated and do not require refuelling they should be kept moving rather than be martialled into large stabling yards or station complexes. (Page 118, HSR Study - Phase 2) - Cost

The 2013 Infrastructure Australia study also concludes that the cost of the Shanghai maglev ($US 39 million / km) is twice the cost of conventional HSR. However, conventional low-speed rail projects in Melbourne have cost twice that amount in recent times (E.g. The 'Regional Rail Link').

Infrastructure Australia's Maglev Analysis

The biggest ever study of fast rail in Australia (2011 - 2013) Infrastructure Australia is dismissive of maglev technology:

|

All HSR systems currently in operation are based on electric traction using traditional steel wheels on rails, but with a range of track and train technology options8. 8) Maglev or magnetic levitation technology systems are excluded from this definition of HSR. (Chapter 1, Page 47, HSR Study, Phase 2) |

Seeing as the project will cost $80 billion (Infrastructure Australia's costing) it is unfortunate that the above is the extent of their consideration of maglev technology.

Monorails Australia's Maglev Proposals

- Melbourne-Geelong maglev proposal. Melbourne to Geelong in 12 minutes with a stop at Avalon Airport.

- Melbourne airport maglev proposal. Melbourne to the airport in 8 minutes.

- Melbourne-Sydney maglev proposal. Melbourne to Sydney in two hours.

- Sydney-Newcastle maglev monorail proposal. Sydney - Newcastle in 25 minutes.

Links & References

- Transrapid quote for Melbourne including the crucial $34 million / km figure for twin track:

Submission in response to the East-West Needs Assessment Report (6 MB PDF) - US Maglev Coalition

Document: Transrapid Maglev Vehicle and Guide way Development Includes passenger numbers for Shanghai maglev as at December 2010. (1 MB PDF)

The Maglev Briefing

For a printable version of this page click here (1.4 MB).

Consolidated Land and Rail Australia (CLARA)

|

JR SC MaglevTest Track (Wikipedia) "In 2011, the ministry gave JR Central permission to operate the SCMaglev system on their planned Chūō Shinkansen linking Tokyo and Nagoya by 2027, and to Osaka by 2045." |

"CLARA is an Australian private group formed to deliver a program to change Australia. We seek to undertake a re-balancing of our settlement and deliver new ways of imagining, planning and building cities, transport and infrastructure." - CLARA Web Site.

Bullet Train For Melbourne

May 15, 2016

Financial Review HSR Story by Bryce Corbett

After years of talk about a very-fast train between Sydney and Melbourne investors are starting to put their money where their mouth is.

A consortium of international and local investors, including General Electric, Japan Rail Central and Mitsui have already purchased more than 37,000 hectares of land between Sydney and Melbourne with a view to fast-tracking the development of a high-speed rail link between the two capitals and the subsequent construction of no less than eight new, purpose-built mini-’cities’.

It’s all happening under the auspices of a local company called Consolidated Land and Rail Australia (CLARA).

Lest you think it all sounds pie-in-the-sky, word on the street is that the mysterious CLARA (whose enigmatic website currently only features two scant pages) boasts an advisory board that includes former US Transport Secretary Ray LaHood, former Clinton adviser David Wilhelm, Joe Biden confidant Mark Doyle and the CEO of American Chamber of Commerce in Australia (AmCham), Niels Marquardt.

Rounding out the high-powered posse are the local likes of former premiers Barry O’Farrell and Steve Bracks.

Japan Rail Central owns the magical “magnetic-levitation” technology, on which CLARA is pinning its hopes to create a rail service that would cut the overland journey from Sydney to Melbourne down to a nifty hour and 50 minutes.

O’Farrell was among a group who visited Japan in early April to test-ride a stretch of rail line between Tokyo and Nagoya where the technology has been honed. BOF even tweeted a photo of himself aboard the speedy new train.

The consortium has already met with Victorian Premier Daniel Andrews and is angling for a sit-down with his NSW counterpart, Mike Baird.

Privately, the PM (who together with his better-half Lucy, chair of the Greater Sydney Commission, love a bit of town planning) is believed to be enthusiastic about the prospect - especially if the $75 billion price tag can be offset with private investment via the much-vaunted “value capture” model of infrastructure funding. Quite apart from all the shiny new toys involved, it’s got legacy written all over it.